Optimize Your Coil Tipper and Coil Upender Handling with Rugged, Customized Equipment

Efficiently moving, positioning, and rotating metal coils is crucial for productivity in metal processing facilities. However, manually handling heavy, awkward coils using lift trucks and pull ropes brings serious risks of injury and equipment damage. Bottlenecks in coil handling can also hamper production by slowing downstream processes.

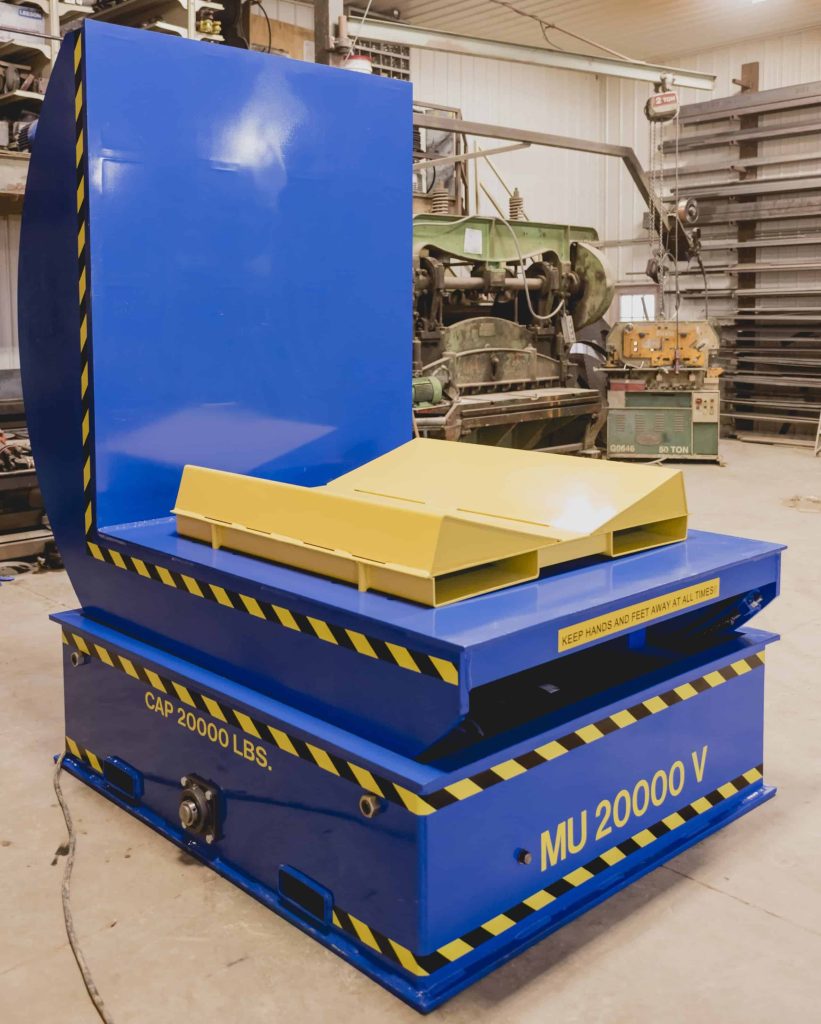

Coil Quip Materials Handling offers heavy-duty coil handling equipment to help you overcome these challenges. Our coil tippers and coil upenders are precision-engineered to boost efficiency, improve safety, and reduce costs throughout your coil utilization operations.

Coil Tipper and Coil Upender: Versatile Power for Optimal Coil Positioning

Coil Quip coil tippers provide a versatile, safe method to accurately rotate metal coils from vertical to horizontal or vice versa. The powerful tipping action allows you to achieve the optimal coil position for your processes, eliminating risky and labor-intensive manual positioning.

Our coil tippers are available in standard stationary and portable configurations. Custom engineering is also available to meet any production line requirements. Common applications include:

- Tipping coils for connection to decoilers or straighteners

- Rotating coils for loading/unloading in various orientations

- Inline integration with downstream cut-to-length or slitting operations

- Adjusting coil position for air/water jet burning tables

- Enabling overhead crane access for coil removal

Standard features include:

- Heavy-duty steel weldment construction

- Precisely machined headstock and tailstock assemblies

- Chain drive rotation with gearbox or hydraulic motor

- Pendant, radio remote, or PLC controls

- Customizable arms, mandrels, and accessories

Portable tippers add the flexibility of a compact wheel-mounted design that can serve multiple production lines. Custom-engineered solutions allow integration with your existing equipment and infrastructure.

Choose from our standard and custom coil tippers to improve line flow and operator safety.

Coil Tippers and Coil Upenders: Tilt Coils Safely with Complete Control

Coil Quip coil tipper and coil upenders provide powered, mechanized tilting to gently rotate coils from the vertical to horizontal position or vice versa. Upenders offer finer position control than tippers for precise coil alignment.

Common applications include:

- Gradual coil rotation for decoiling or inspection

- Tilting coils for air/water jet cutting tables

- Adjusting coil position for loading/unloading

- Integration with straighteners, feed tables, stackers

- Enabling overhead crane coil removal

We offer a full range of upender types including:

- Rotary Upenders: Provide 360-degree rotation for total coil control. The rotary cradle with powered rollers enables infinite position adjustments.

- Tilting Upenders: Offer 90-degree tilt control from vertical to horizontal. The pivoting cradle provides firm coil support.

- Low-Profile Upenders: Allow horizontal loading in tight spaces. The pit-mounted dolly lifts coils for precise tilting control.

Standard upender features:

- Rigid steel weldment construction

- Heavy-duty rotation bearings and gear drives

- Variable-speed AC control drives

- Radio or pendant controls

- Cradle assemblies to match coil sizes

- Custom integration and automation

Upenders eliminate risky forklift manipulation by providing powered, highly controlled coil rotation. Choose Acme to match robust upender designs with your specific application needs.

Engineered for Reliable, Low-Maintenance Operation

Engineered for Reliable, Low-Maintenance Operation

All Coil Quip coil handling equipment is engineered for durable long-term operation with minimal maintenance needs. Customers count on our products for reliable productivity under punishing demands:

- Structural steel frames withstand enormous torque loads

- Large-diameter slewing rings designed for long service life

- Pre-loaded tapered roller bearings for optimal radial and axial capacity

- Precision-cut alloy steel gears and chains with service factors >1.25x

- Motors and hydraulics selected based on application duty cycles

- Waterproof radio controls and NEMA 4 electrical enclosures

- External lubrication ports and filtered breather vents

- Finishes include hot dip galvanizing and durable powder coats

Proper maintenance optimizes uptime. We use proven industrial components designed for simplified servicing. Customers also benefit from:

- Comprehensive documentation with recommended maintenance schedules

- Easy access for visual inspections and routine upkeep

- Interchangeable standard replacement parts

- Extended warranties on major components

- Technical support from our service team

When productivity relies on your equipment, there’s no room for downtime. Coil Quip coil handling products deliver the optimum balance of rugged design and maintenance accessibility.

Intuitive Controls Simplify Operation

Controlling tons of steel safely requires responsive, precise systems. Coil Quip coil handling equipment is equipped with the latest intelligent control interfaces. This simplifies use and allows fine-tuned movements.

Standard control features include:

- Pendant stations with speed potentiometers

- E-stop, jog, and braking functions

- Radio remote controls with bellybox

- Lengths up to 200 feet for operation away from coils

- Programmable controls like PLCs and CNCs

- Networking for centralized production monitoring

Our control packages are tailored to each application. Available options include:

- Touchscreen HMI for recipe-based automation

- Master/follower configurations

- Integration with upstream/downstream processes

- Advanced sensors for positioning, RPM, load, etc.

- SCADA and industrial networking

- Customizable buttons, feedback, and safety interlocks

Intuitive controls mean faster set-up, simpler changeovers, and reduced risks. Based on your operational objectives, our experts select the ideal technologies to maximize ease of use.

Seamless Integration Minimizes Disruption

Whether you are looking to enhance existing lines or build new ones, Coil Quip specializes in turnkey integration. Our experienced application engineers ensure your coil handling equipment achieves seamless compatibility with upstream and downstream processes.

To limit production line disruption, we offer:

- Dimensional drawings to confirm coil handling equipment fits within available space

- Modeling of material flow bottlenecks to optimize equipment placement

- Electrical and control modifications for plug-and-play installation

- Custom risers, platforms, and foundations to properly interface with your infrastructure

- On-site support for installation, debugging, and operator training

- Documentation for maintenance and replacement component sourcing

Lack of integration forethought risks unnecessary downtime, hazards, and added costs. By partnering with our integration experts early in your project, we engineer solutions for maximum productivity.

Detailed Analysis Provides Data-Driven Decisions

Efficient coil handling relies on equipment properly sized and configured for each operation. Our application engineers will conduct a detailed assessment, including:

- Evaluation of all relevant coil and production line parameters

- Time studies to identify handling bottlenecks and constraints

- Analysis of floor space, crane access, and infrastructure

- Documentation of key safety risks and ergonomic challenges

- Review of current and future production requirements

Armed with this data, we provide transparent equipment types, capacities, features, and layout recommendations. Our team will also conduct an in-depth cost-benefit analysis quantifying:

- Estimated improvement in material flow

- Projected reduction in manual handling

- Anticipated decrease in safety incidents

- Expected maintenance and downtime

- Return on investment timeline

This assessment ensures informed, justifiable purchasing decisions optimized for your operational objectives. We also use this data to deliver highly customized solutions.

Partner with the Coil Tippers and Coil Upender Handling Experts

Efficient coil handling is crucial for productivity and safety. However, finding the suitable material handling solutions can be challenging. By partnering with Coil Quip, you tap into decades of experience optimizing coil operations worldwide.

To learn more about our coil tippers, coil upenders, professional assessments, and integration services, contact Coil Quip today. Our passionate engineers are ready to help customize productive, long-lasting equipment that seamlessly fits your facility.

Q: What is an upender?

A: An upender is a piece of handling equipment used to rotate or invert objects, such as coils or pallets, from a horizontal to a vertical position.

Q: How can I optimize my coil tipping and upending process?

A: You can optimize your coil tipping and upending process by using rugged and customized equipment specifically designed for your material handling needs.

Q: What is a coil upender?

A: A coil upender is a type of upender specifically designed for handling and rotating steel coils.

Q: What can an upender machine do?

A: An upender machine can rotate and invert palletized steel coils, allowing for easier unloading and handling.

Q: How does a coil manipulator work?

A: A coil manipulator allows the user to transfer palletized steel coils from a horizontal to a vertical position using hydraulic cylinders.

Q: What is a coil cart?

A: A coil cart is sometimes called a coil positioner and is a mobile handling device used to safely transport and store steel coils.

Q: Can an upender handle coils at a 90° angle?

A: Yes, an upender can handle coils at a 90° angle, allowing for efficient storage and transportation of the coils.

Q: What is the maximum weight that an upender can handle?

A: The maximum weight that an upender can handle depends on the specific model and its specifications, but typically it can handle several thousand pounds.

Q: What are some advantages of using an upender for coil handling?

A: Using an upender for coil handling allows for safer and more efficient loading, unloading, and storage of coils. It also helps to prevent damage to the coils during handling.

Q: Where can I find rugged and customized upender equipment?

A: Green Valley Manufacturing is a company that specializes in providing rugged and customized upender equipment for various material handling needs.

Q: How can an upender improve my material handling process?

A: An upender can improve your material handling process by providing a safe and efficient way to rotate and invert objects, such as coils or pallets, saving time and reducing the risk of injuries.